ADRO: Engineering Revolution and the Carbon Fiber Benchmark

In the automotive aftermarket world, enthusiasts are often forced to choose between aesthetics and performance. ADRO (Aerodynamic Development Race Optimization) was founded to eliminate this compromise. More than just a body kit manufacturer, ADRO is a design house and engineering firm that bridges the gap between OEM+ luxury aesthetics and track-proven functionality.

The brand's design language is curated by Chief Designer Davis Lee, whose prestigious resume includes work with Mercedes-Maybach and Rivian. His philosophy is distinct: aftermarket parts should not look like foreign additions; they should enhance and evolve the vehicle's original lines. By utilizing advanced 3D scanning and Computational Fluid Dynamics (CFD), ADRO creates components that fit perfectly and perform exceptionally.

ATOMIC-SHOP is proud to be an authorized partner of ADRO, offering the complete range of authentic components for BMW, Tesla, Toyota GR, and Hyundai N platforms. This is the ultimate choice for drivers who demand engineering excellence.

The Technology: Why Pre-preg Carbon is the Professional's Choice

When purchasing carbon fiber, you are paying for weight reduction and structural rigidity. However, the market is flooded with "Wet Carbon," which is often heavy and purely cosmetic. ADRO specializes in Pre-preg (Dry Carbon) technology, the same manufacturing process used in Formula 1 and aerospace.

"Pre-preg" means the carbon fiber fabric is impregnated with a precise amount of resin at the factory level. The components are then cured in an autoclave under high heat and immense pressure. This process eliminates air bubbles and excess resin, resulting in a product that is structurally superior.

| Feature | Standard "Wet" Carbon | ADRO Pre-preg (Dry) Carbon |

|---|---|---|

| Resin-to-Fiber Ratio | Poor. Excessive resin adds unnecessary weight and brittleness. | Optimal. Maximum fiber density for superior strength. |

| Weight | Heavy. Often uses fiberglass backing to cut costs. | Ultra-lightweight. Typically 40-60% lighter than wet carbon. |

| Fitment Consistency | Low. Prone to warping during the curing process. | OEM-Grade. Molded under pressure for precise dimensions. |

Comprehensive Product Breakdown

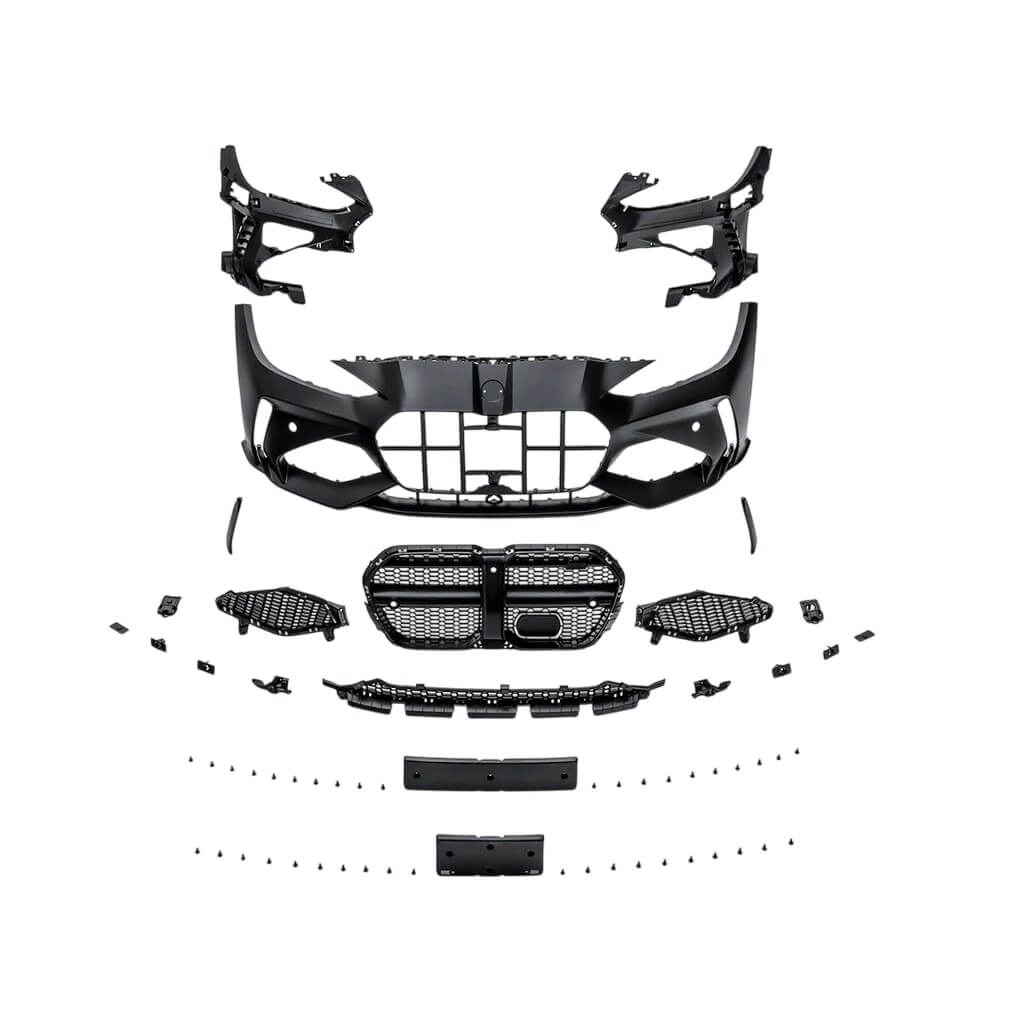

ADRO does not design parts merely for visual impact; each component serves a purpose:

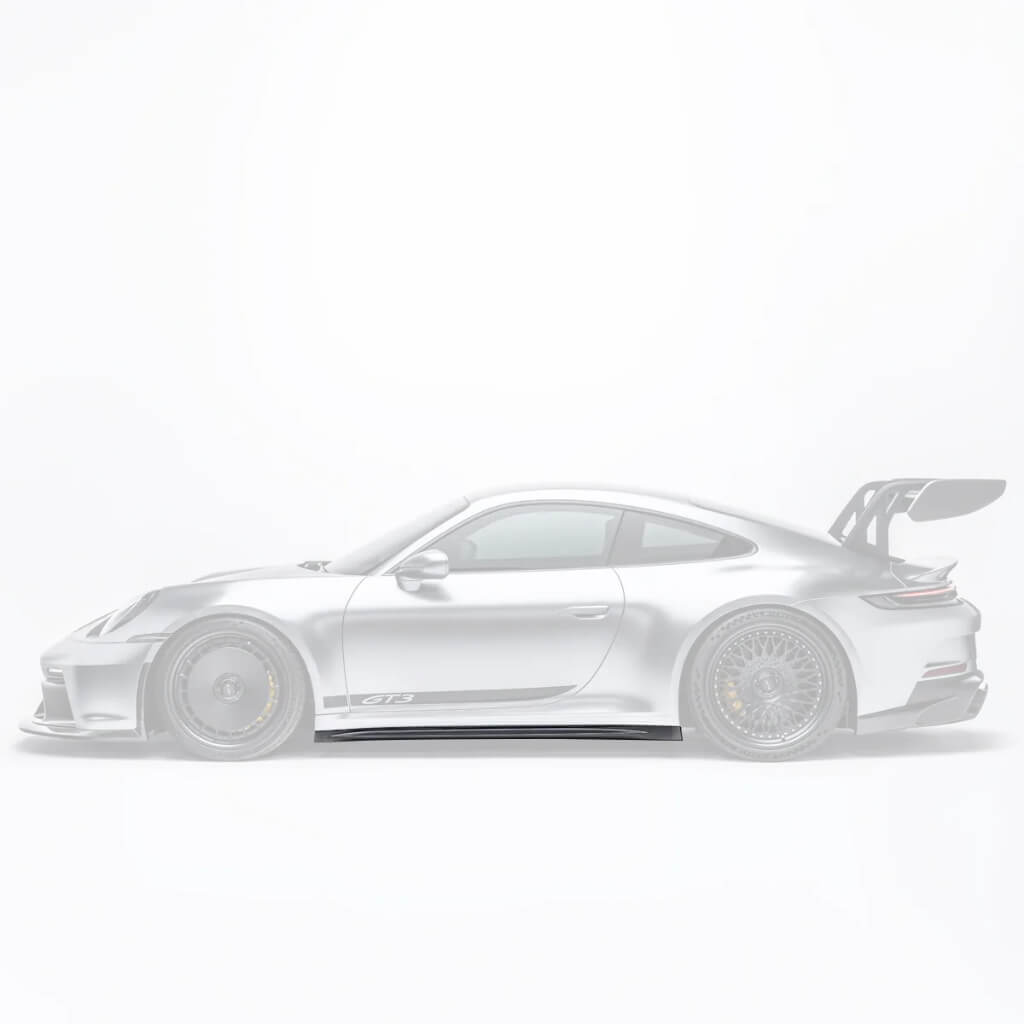

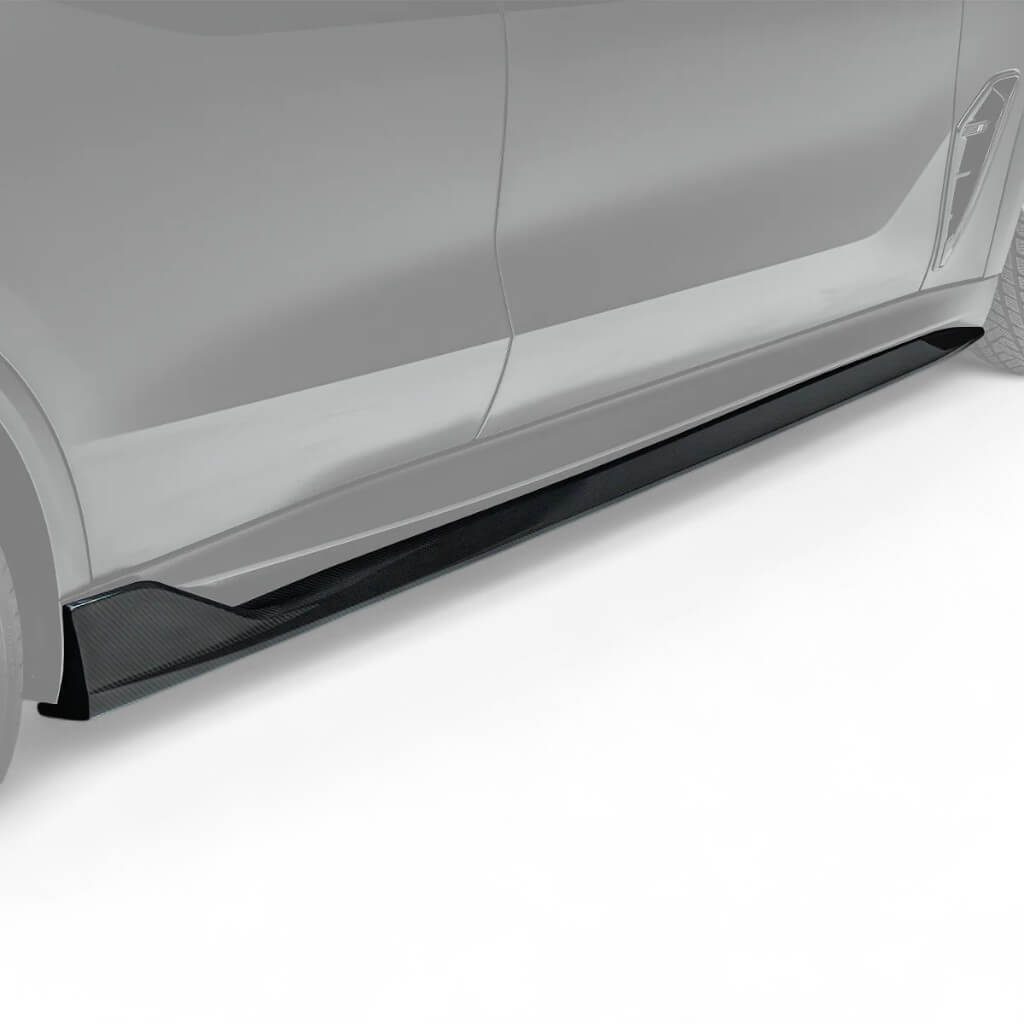

- Front Splitters & Lips: Engineered to manage the airflow underneath the vehicle. A properly designed splitter creates a high-pressure zone above it and low pressure below, effectively "sucking" the front tires onto the road for improved turn-in response and high-speed stability.

- Rear Diffusers: Perhaps the most critical aero component. ADRO diffusers feature aggressive vertical strakes that organize the turbulent air exiting from beneath the chassis. This reduces drag and improves the vehicle's aerodynamic wake.

- AT-R Swan Neck Wings: Utilizing top-mounted "swan neck" uprights, these wings keep the critical underside surface free from airflow disturbance. This maximizes the efficiency of the wing, generating significant downforce for track applications.

- Premium Widebody Kits: ADRO widebody kits are masterpieces of integration. Instead of looking like bolted-on aftermarket flares, they flow seamlessly with the car's existing body lines, allowing for wider wheel fitments while maintaining a cohesive, factory-concept appearance.

Frequently Asked Questions (FAQ)

Does the aerodynamics actually work, or is it just for looks?

It works. ADRO relies heavily on Computational Fluid Dynamics (CFD) during the development phase. This allows engineers to simulate airflow around the digital model of the car, ensuring that the components reduce drag or increase downforce in the real world. You are buying verified performance, not just aesthetics.

Do ADRO parts fit perfectly "out of the box"?

Yes. Because ADRO utilizes 3D scanning of the OEM vehicle chassis, the fitment is industry-leading. Most front lips, side skirts, and diffusers are designed to install using factory mounting points or high-strength 3M tape provided in the kit. This "bolt-on" philosophy saves you time and money at the body shop.

Do the parts come painted or finished?

All ADRO carbon fiber components arrive fully finished. They are coated with a premium, high-gloss clear coat that is UV-stabilized to prevent yellowing or fading from sun exposure. The finish is comparable to the paint quality of a high-end luxury vehicle, ready to install immediately.