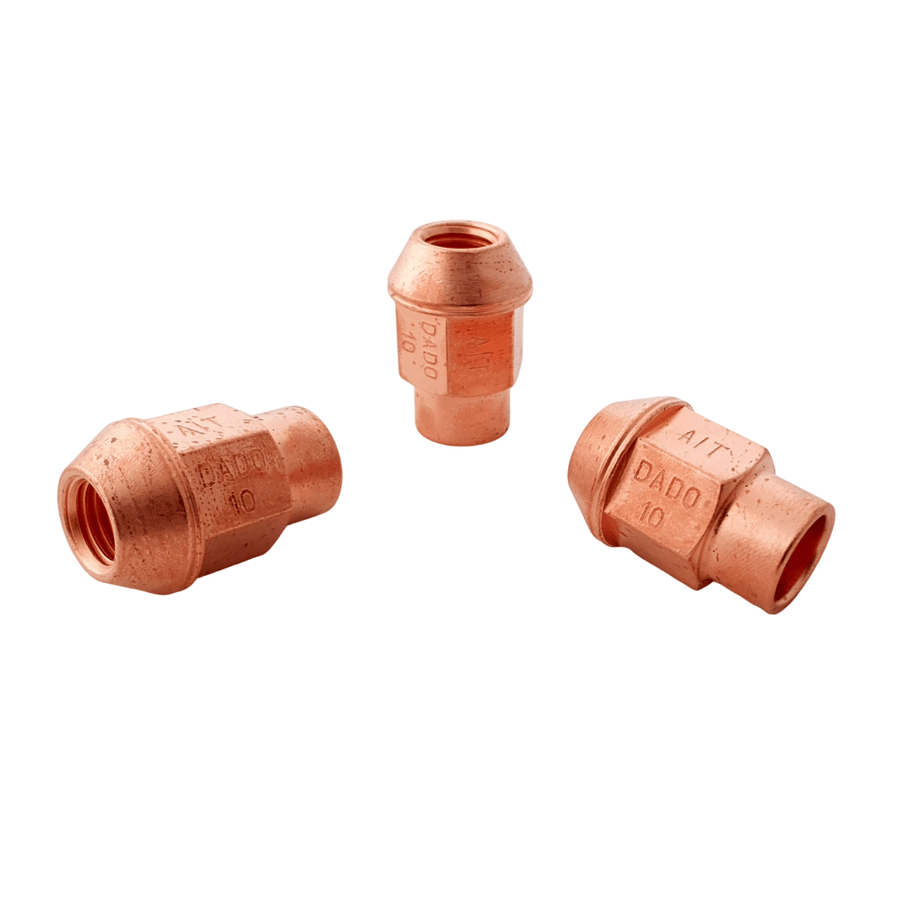

A.I.TECH: Brake Component Engineering for Superior Thermal Stability and Control

Under high-load conditions—whether it's repeated stops on the highway, dynamic city street driving, or a track day—the braking system functions as a complex thermodynamic unit. Deceleration efficiency is determined not only by an aggressive initial "bite" but by the system's ability to manage thermal energy consistently. A.I.TECH is a European engineering brand specializing in brake rotors and pads where the balance of metallurgy, geometry, and ventilation is paramount.

ATOMIC-SHOP Ukraine is the official A.I.TECH supplier. We offer solutions that allow factory braking systems to operate beyond OEM limits, ensuring a predictable pedal even at critical temperatures.

Why Do Stock (OEM) Brakes Fail Under Pressure?

Factory components are designed for the average driver, prioritizing NVH comfort (noise and vibration suppression). However, spirited driving reveals systemic flaws:

- Thermal Fading: Overheating of the friction layer, leading to a "spongy" or sinking pedal.

- Thermal Distortion: Rotor warping due to uneven cast iron expansion, causing steering wheel judder.

- Material Degradation: Micro-cracking on the rotor surface during intense thermal cycling.

A.I.TECH mitigates these risks through the use of High Carbon cast iron and specific ventilation channel architecture.

Comparative Table: OEM Rotors vs. A.I.TECH High-Performance

| Parameter | OEM Brake Rotors | A.I.TECH Engineering |

|---|---|---|

| Material Composition | Standard Grey Cast Iron | High Carbon Cast Iron (HC) |

| Thermal Conductivity | Base (prone to hot spots) | Enhanced (rapid energy dissipation) |

| Ventilation | Straight Vanes | Directional or Pillar Vane cooling |

| Vibration Resistance | Moderate | High (due to HC metal structure) |

| Operating Range | Up to 350-400°C | Stable up to 600-650°C |

A.I.TECH Friction Materials: "Friction Plateau" Stability

The primary engineering feature of A.I.TECH pads highlighted by ATOMIC-SHOP is the friction coefficient ($\mu$) stability. Unlike budget alternatives where grip drops sharply after heating, A.I.TECH pads are engineered with a wide thermal window. This provides the driver with:

- Linear Response: Deceleration force directly proportional to pedal pressure.

- Short Bed-in: Rapid seating due to a specialized thermal layer on the pad surface.

- Brake Pad Stability: No "glazing" during long descents or intense stop-and-go traffic in cities like Kyiv.

A.I.TECH Application Table by Scenario

| Scenario / Vehicle Class | Recommended Combination | Result in Ukraine's Conditions |

|---|---|---|

| Hot Hatch / Sport Street | Slotted Rotors + Street/Track Pads | Zero fade after repeated high-speed stops |

| Track Days / Time Attack | HC Rotors + Racing Pads | Consistent lap times without brake degradation |

| Heavy SUV (BMW X5, Audi Q7) | Reinforced HC Rotors + Heavy-Duty Pads | Safe heavy-mass braking from high speeds |

FAQ: ATOMIC-SHOP Technical Expertise on A.I.TECH

Will slotted rotors squeal during braking?

A.I.TECH slots are designed to effectively vent gases and clean the pad surface while minimizing acoustic discomfort. A slight characteristic sound may occur under extreme loads, which is normal for high-performance systems.

Is the "Bedding-in" procedure mandatory?

Yes. Proper bedding ensures an even friction layer transfer from the pad to the rotor. This is critical to prevent future vibrations and to achieve the rated friction coefficient.

Can I use A.I.TECH pads with stock rotors?

Yes, this is an excellent "Stage 1" upgrade. However, maximum efficiency and fade resistance are achieved when paired with A.I.TECH High Carbon rotors, which possess the necessary heat capacity.